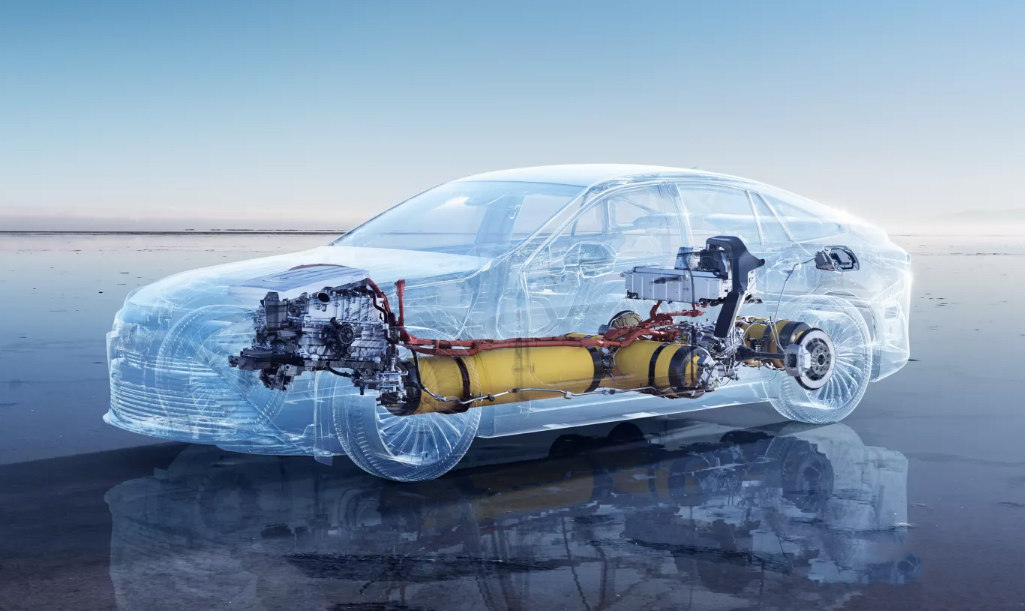

A sakamakon sauyin makamashi na duniya mai sauri, ƙwayoyin man fetur na hydrogen, a matsayin muhimmin mai ɗaukar makamashi mai tsabta, suna haifar da damar ci gaba da ba a taɓa gani ba. Haɗakar lantarki ta membrane (MEA), a matsayin babban ɓangaren ƙwayar mai, tana shafar inganci da tsawon rayuwar dukkan tsarin tantanin halitta. Daga cikin waɗannan, tsarin shirya takardar carbon mai yaduwa ta iskar gas (GDL), musamman tsarin warkarwa da ƙera shi, yana ƙayyade tsarin porosity, watsa wutar lantarki, da ƙarfin injina na GDL.

Mahimman Mahimman Mahimman Mahimman Mahimman Magani da Magani a Samar da Takardar Carbon ta GDL

Ga masu kera takardar carbon ta GDL don ƙwayoyin mai na hydrogen, mabuɗin cin nasara a kasuwa shine ko za su iya samar da takardar carbon mai inganci tare da kyakkyawan daidaito a cikin kwanciyar hankali, inganci, da kuma araha. Kayan aikin samarwa na gargajiya (kamar mashinan lebur da mashinan birgima) suna haifar da cikas da yawa a kan hanyar samar da manyan kayayyaki.

Mataki na 1 na Jin Zafi: Rashin daidaiton samfura, ƙarancin yawan amfanin ƙasa, da wahalar isar da kayayyaki da yawa.

Matsalolin Gargajiya: Matsi mai faɗi na gargajiya yana shafar daidaiton sarrafa faranti masu zafi da kuma nakasar zafin faranti bayan dumamawa, wanda ke haifar da babban karkacewa a cikin daidaiton kauri na takardar carbon da aka warke. Bugu da ƙari, hanyar matsi mai katsewa tana ba da damar samar da takardu na takamaiman girma, wanda hakan ke sa ba zai yiwu a samar wa abokan ciniki birgima masu girma dabam-dabam ba. Matsi na birgima na gargajiya yana amfani da matsin lamba ta hanyar hulɗar layi, tare da raguwar matsin lamba daga tsakiyar birgima zuwa ƙarshen, yana sa takardar carbon ta kasance matse a tsakiya kuma ta saki a gefuna. Wannan kai tsaye yana haifar da kauri mara daidaituwa da rarraba ramuka marasa daidaituwa. Ko da a cikin rukuni ɗaya, ko ma takardar carbon iri ɗaya, aiki na iya canzawa, tare da yawan amfanin ƙasa yana kusan kashi 85% a cikin dogon lokaci, yana haifar da babban haɗari ga isar da oda mai yawa.

Maganin matsin lamba na Mingke: Fasahar isostatic tana cimma matsaya iri ɗaya ta gaske bisa ga dokar Pascal ta makanikan ruwa. Kamar matsin lamba na hydrostatic a cikin zurfin teku, tana aiki iri ɗaya akan kowane yanki na takardar carbon daga kowane bangare.

SakamakoTasiri:

- Daidaito a Kauri:Daidaita juriyar kauri daga microns goma sha biyu zuwa ciki±3μm.

- Daidaiton ramuka: Ana iya kiyaye ramuka akai-akai a babban ma'aunin kashi 70% ±2%.

- Inganta Yawan Yawa: Yawan yawan ya karu daga kashi 85% zuwa sama da kashi 99%, wanda hakan ya ba da damar isar da kayayyaki cikin kwanciyar hankali, babba, da inganci.

Mataki na 2 na Ciwo: Ƙarancin ingancin samarwa, manyan matsaloli a fannin iya aiki, da kuma tsadar farashi mai yawa.

Matsalolin Gargajiya: Yawancin hanyoyin laminating masu inganci suna da 'tsari', kamar tanda gida, ana gasawa sau ɗaya a lokaci guda. Saurin samarwa yana da jinkiri, ana kunna kayan aiki akai-akai kuma ana kashe su, yawan amfani da makamashi yana da yawa, dogaro da aiki yana da ƙarfi, kuma rufin ƙarfin yana cikin sauƙi.

Maganin Isostatic na Mingke: An tsara injin matse mai bel biyu a matsayin rami mai aiki akai-akai mai 'zafi mai zafi da matsin lamba mai yawa'. Tsarin yana shiga daga gefe ɗaya, yana tafiya ta hanyar cikakken tsari na matsewa, warkarwa, da sanyaya, kuma ana ci gaba da fitarwa daga ɗayan ƙarshen.

Tasirin Magani:

- Tsawaita Samarwa: Yana ba da damar samar da kayayyaki na tsawon awanni 24, tare da saurin da ke kaiwa mita 0.5-2.5 a minti daya, da kuma samar da kayayyaki har zuwa murabba'in mita miliyan 1 a kowace layin samarwa, wanda hakan ke kara inganci da fiye da sau biyar.

- KudinNarkewa: Tasirin sikelin samarwa mai ci gaba yana rage raguwar darajar kayayyaki, makamashi, da kuma farashin aiki a kowace murabba'in mita.Ma'auni suna danunancewa jimlar farashin samarwa za a iya rage shi da kashi 30%.

- Tanadin Ma'aikata: Babban matakin sarrafa kansa yana ba da damar rage yawan ma'aikata da kashi 67% a kowane aiki.

Mataki na 3 na Ciwo: Tagar tsari mai kunkuntar, tsadar gwaji da gyara kurakurai, da ƙarancin ƙirƙira

Matsalolin Gargajiya: Aikin takardar carbon ta GDL yana da matuƙar tasiri ga yanayin zafi da lanƙwasa. Kayan aikin gargajiya ba za su iya sarrafa zafin jiki daidai ba kuma suna da lanƙwasa matsi ɗaya, wanda hakan ke sa ya yi wuya a kwaikwayi tsarin da ya fi dacewa da dakin gwaje-gwaje. Kuna son gwada sabon dabara ko sabon tsari? Zagayen gyara kurakurai yana da tsawo, ƙimar lahani tana da yawa, kuma farashin gwaji da kuskure yana da ban tsoro.

Maganin matsin lamba na Mingke: Yana samar da dandamali mai sassauƙa kuma mai sauƙin sarrafawa.

Tasirin Magani:

- Daidaitaccen Kula da Zafin Jiki: Kula da zafin jiki mai zaman kansa na yankuna da yawa tare da daidaito har zuwa ± 0.5℃, yana tabbatar da cikakken warkar da resin.

- Matsi Mai Daidaitawa: Ana iya saita matsi daidai kuma a kiyaye shi a cikin kewayon sandunan 0-12 don daidaiton daidaito.

- Tsarin aikiFitowa: Da zarar an sami mafi kyawun sigogi, ana iya "kulle" su da dannawa ɗaya a cikin tsarin, don cimma nasarar sake haɓaka tsari 100% da kuma tabbatar da ingantaccen aikin samfur.

- Ƙarfafa Bincike da Ci gaba: Nanjing Mingke a halin yanzu tana da digiri biyu a fannin bincike da ci gabamai ƙarfi- injunan gwajin mashinan bel mai injuna, suna samar da ingantaccen dandamali na gwaji na matakin samarwa don bincike da haɓaka sabbin kayayyaki da sabbin tsare-tsare, suna rage shingayen kirkire-kirkire da haɗari sosai. A lokaci guda, ga kamfanoni masu ƙarancin jarin farko da wahalar siyan kayan aiki, ana iya bayar da ayyukan kera ƙananan rukunin kwangila waɗanda suka kama daga mako guda zuwa wata ɗaya don inganta ƙwarewar isar da kayan takarda na carbon, taimakawa kasuwanci wajen gudanar da samar da kayan gwaji na farko, rage yawan saka hannun jari a kayan aiki, daragehaɗari.

Mataki na 4 na Ciwo:Ragowar manne mai gyaran phenolic, yawan asarar takardar saki ko kayan taimako na wakili mai sakin kaya,s.

Matsalolin Gargajiya: Bayan an yi amfani da resin phenolic, yana da wuya a raba shi da farantin matsewa ko bel ɗin ƙarfe. Kamfanonin gargajiya gabaɗaya suna amfani da wakilan saki ko takardar saki don cimma tsarin rushewa, amma wakilan saki masu inganci ko takaddun saki masu inganci suna da tsada a saya, kuma yawan amfani da su yayin aikin samarwa yana ƙara farashin samar da takardar carbon, wanda ba ya haifar da farashin kayayyaki masu gasa a kasuwa.

Maganin Isostatic na Mingke: Injin bel ɗin ƙarfe biyu na Mingke mai ɗaukar hoto yana bawa abokan ciniki damar zaɓar bel ɗin ƙarfe mai ɗauke da chrome.

Tasirin Magani: Ta hanyar gwaje-gwajen ciki da aka gudanar a masana'antar Mingke ta amfani da bel ɗin ƙarfe mai rufi da chrome akan takardar carbon mai warkarwa, an gano cewa idan aka kwatanta da bel ɗin ƙarfe na gargajiya, bel ɗin ƙarfe mai rufi da chrome yana ba da ingantaccen aikin resin da kuma sakin aiki. Ragowar manne mai yawa yana da sauƙin cirewa, kuma idan aka yi amfani da shi da goga mai tsaftacewa ta hannu, sauran manne da ke saman bel ɗin ƙarfe za a iya kawar da shi cikin sauƙi, yana taimaka wa abokan ciniki rage farashi akan abubuwan saki da takardar saki. Layer ɗin chrome da ke saman bel ɗin ƙarfe yana inganta tauri da juriyar lalacewa na bel ɗin sosai. Bugu da ƙari, fim ɗin oxide mai yawa da Layer ɗin chrome ya samar akan saman bel ɗin ƙarfe yana toshe lalacewar iskar oxygen, ruwa, da sauran abubuwan lalata, ta haka yana tsawaita rayuwar bel ɗin ƙarfe.

Ga masu amfani waɗanda suka daɗe suna dogara da kayan aiki da aka shigo da su daga ƙasashen waje, Nanjing Mingke, a matsayin kamfanin cikin gida, tana ba da mafita mafi kyau:

- Sauya kayan cikin gida: Karya ikon shigo da kaya daga waje, tare da fa'idodi a cikin siyan kayan aiki da farashin kulawa.

- Amsar gaggawa ta sabis: tallafin fasaha na awanni 24, injiniyoyi a wurin cikin awanni 48, magance jinkirin amsawa bayan siyarwa da kuma dogon zagayen kayan gyara na kayan da aka shigo da su.

Sakamakon aikace-aikacen gaske: ƙirƙirar ƙima mai mahimmanci ga abokan ciniki

Bayan da wani sanannen kamfanin samar da man fetur na hydrogen ya rungumi na'urar buga belin ƙarfe mai siffar isostatic ta Minke, ya sami sakamako mai kyau wajen samar da takardar carbon ta GDL.

- Babban ci gaba a yawan amfanin gona: ya karu daga kashi 85% a cikin hanyoyin gargajiya zuwa sama da kashi 99%.

- Babban ci gaba a cikin ingancin samarwa: ƙarfin fitarwa na yau da kullun ya kai murabba'in mita 3,000.

- Rage amfani da makamashi: yawan amfani da makamashi ya ragu da kashi 35%.

Inganta Ayyukan Samfura:

- Daidaiton ramuka: 70% ± 2%

- Juriyar Cikin Jirgin Sama: < 5 mΩ·cm

- Juriyar Tafiya-Jirgin Sama: < 8 mΩ·cm²

- Ƙarfin Tashin Hankali: > 20 MPa- Kauri Daidaito: ±3 μm

Kammalawatsarin sabis da tallafin fasaha

Nanjing MingkeTsarin aikiSystems Co., Ltd. tana ba wa abokan ciniki cikakken tallafin fasaha:

1. Tallafin Ci Gaban Tsarin Aiki

Aƙungiyar ƙwararru ta fasaha tana taimaka wa abokan ciniki wajen inganta sigogin tsari da daidaita kayan aiki, tabbatar da cewa kayan aikin sun cika takamaiman buƙatun tsarin samarwa.

2. Ayyukan Kayan Aiki na Musamman

Bayar da ayyukan kayan aiki na musamman bisa ga buƙatun musamman na abokan ciniki, gami da girma dabam-dabam, tsare-tsare na musamman, da sauransu.

3. Ayyukan Shigarwa da Gudanar da Ayyuka

Ƙwararrun ƙungiyar injiniya suna ba da ayyukan shigarwa da kuma aiwatar da ayyuka a wurin don tabbatar da cewa ana iya shigar da kayan aiki cikin sauri.

4. Horar da Fasaha

Bayar da cikakken horo na aiki da kulawa don tabbatar da cewa abokan ciniki za su iya aiki da kuma kula da kayan aikin yadda ya kamata.

5. Tallafin Bayan Siyarwa

Kafa tsarin mayar da martani cikin sauri na awanni 24 don samar da sabis na bayan tallace-tallace da tallafin fasaha akan lokaci, don tabbatar da samarwa ba tare da katsewa ba.

Masana'antar tana da fa'idodi masu yawa na amfani.

Mashin ɗin bel ɗin ƙarfe mai ƙarfi na Mingke mai ƙarfi ba wai kawai ya dace da samar da takaddun carbon na GDL don ƙwayoyin mai na hydrogen ba, har ma ana iya amfani da shi sosai a fannoni da yawa:

- Kwayoyin mai: Takardar carbon ta GDL, shirye-shiryen Layer mai kara kuzari;

- Batirin yanayin ƙarfi: matse takardar lantarki da molded;

- Kayan haɗin gwiwa: shirye-shiryen prepreg na carbon fiber;

- Takarda ta musamman: matsewa mai yawa da ƙera abubuwa;

- Sabbin kayan makamashi: shirya kayan fim masu siriri daban-daban masu aiki.

Amfanin Mingke Double Steel Belt Isostatic Press:

Nanjing Mingke ta shafe shekaru goma tana inganta fasaharta kuma tana ci gaba da zuba jari a cikin bincike da haɓaka na'urorin matse ƙarfe biyu masu ɗaukar hoto. Yanzu suna da na'urorin matsewa masu zafi waɗanda ke kaiwa 400°C tare da daidaitaccen matsin lamba a cikin ±2%. Godiya ga wannan ƙwarewar fasaha, Mingke shine mafi kyawun zaɓi don na'urorin matsewa masu matsewa na carbon idan aka yi la'akari da ƙimar kuɗi da ƙarancin haɗari. A zamanin yau, yawancin kamfanonin matsewa na carbon-to-roll na cikin gida suna zaɓar Nanjing Mingke a matsayin abokin tarayya.

Lokacin Saƙo: Oktoba-09-2025